Business Planning

Modules

- Bills of Resources *

- Capacity Planning

- Manufacturing Resource Planning *

- Purchase Order Processing

- Installation

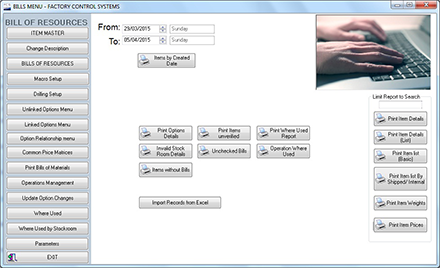

Bills of Resources

The Bills of Resources Module provides the foundation for the system, by explicitly defining the relationships between your parts and products, and specifying how they work together.

It ensures that: Sales Order Processing, Manufacturing and Purchasing, are all driven by the same information.

A full database library is available for all finished products, components and services. These are organised by item code and description.

You have the ability to set up unlimited multi-level Bills of Resources for materials and labour, which are parametric, configurable and link to optional sub-bills.

Our unique "Options" feature allows you to easily select from multiple and variable product options, such as: carcase colour, edging colour, handing, fabric etc. These are stored in the products Bills of Resources and subsequently shown in the Customer Order Processing module, for order entry, customer quotations and costings. They can be entered without having to make a fresh Bill of Resources for each new product, on each occasion.

New records can be added to the Libraries of "Options" at any time; and will automatically be available for future use.

Bi-directional communication can be set up with CAM systems, such as AlphaCam and Albatros (for drilling machines). Relationships can be established between Macros in your CAM system and FCS, based on rules you select for parents, parts and sizes.

Formulae for operational times, quantities and sizes can be easily entered in the Bills of Resources, to facilitate fully parametric bills.

Bills can be copied, renamed and edited for fast creation of similar bills.

The Operations Management Menu allows you to edit operations and production time, for multiple bills simultaneously. Similarly, you can swap components on many bills based on your search criteria.

There is a feature to monitor labour and material shrinkage and wastage.

“Where Used” data, can be viewed, enabling you to quickly find all “parents” of a component.

Fluid applications, such as lacquer, paint, glue etc. are automatically calculated, based on the density, coverage and number of coats required.

You must be logged in to post a comment.